Ten (10) Tips on Hydrogen System Valves

What is the acceptable level of leakage for valves in a hydrogen system?

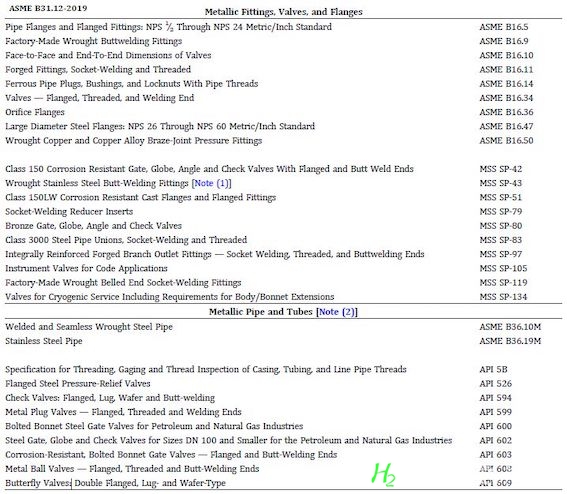

1. Valves shall conform to the standards and specifications shown in the picture of this post.

2. You have to check valves in hydrogen service at least annually.

3. During helium leak tests of valves in the open position, leakage shall not exceed 1 × 10−8 mL/s when differential pressure between the atmosphere and internal passages of the valves is greater than 100 kPa (14.6 psi).

4. Valve end connections requiring welding, brazing, preheating or PWHT procedures shall preserve the seat tightness of the valve.

5. Extended bonnet valves are recommended, where necessary, to establish a temperature differential between the valve stem packing and the fluid in the piping, to avoid packing leakage and external icing or other heat flux problems. The valve should be positioned to provide this temperature differential. Consideration should be given to possible packing shrinkage in low-temperature fluid service.

6. You need to follow the ISO 19880.3 requirements for the safety performance of valves used in gaseous hydrogen stations.

7. You have to follow ISO 23826 requirements for the design, type testing, and examnation requirements for ball valves.

8. AFPM Doc AM-12-50 guideline covers hydrogen system valve design, design to limit losses, and metallurgy, including high-temperature applications.

9. Hydrogen fire-safe vale should be as per API 607 & and ISO 10497.

10. Threaded joints with a suitable thread seal are acceptable for use in gaseous hydrogen systems but are to be avoided in liquid hydrogen systems.

References:

a- ISO 19880.3 Fuelling stations valve

b- ISO 23826 Gas cylinders - ball valves

c- AFPM Doc AM-12-50

d- ASME B31.12, 2019

e- EIGA Doc 121 / 14

平台声明:该文观点仅代表作者本人,零碳未来网 系信息发布平台,我们仅提供信息存储空间服务。

发表评论 取消回复